5 Tips for Setting Up Automotive Oscilloscope Testing

5 Tips for Setting Up Automotive Oscilloscope Testing

Basic Automotive Oscilloscope Training

IF YOU are new to using oscilloscopes for automotive diagnostics or sometimes have challenges in displaying waveforms, this article is for you. We’ll look at the basic scope settings you need to get a waveform every time.

I have five easy tips for you that I follow every time I use the oscilloscope, and that I share with Master Technicians and Technical Trainers globally to help them get a waveform fast. Pay special attention to tip number 5 – the most challenging yet crucial aspect in mastering oscilloscope diagnostics.

Understanding Your Targets and Choosing the Right Equipment

First of all, it goes without saying, “If you don't know what you're looking for, you're going to be doomed from the start.” So make sure you know which connectors you want to measure. Check the wiring diagram for pin numbers and cross-reference the wire colors just to be sure. They sometimes get it wrong.

Now if you don't already own an oscilloscope, they can be expensive, I have a budget-friendly recommendation for you — the 2000 series PicoScope, priced just over $100. Remarkably, it performs some of the functions found in the top-tier PicoScope automotive kit. I also recommend getting some of the Hantek automotive oscilloscope leads, and they're great value at 10 pounds each.

Tip 1: Test Your Setup

Let's kick off with tip number one; test your setup. When you've got your oscilloscope set up and ready to go, don't go straight in. Simply check the operation of the oscilloscope by measuring the battery voltage. A flat line around 12V will indicate that the scope is all connected up and working. This initial step ensures that if you encounter challenges obtaining the waveform, at least you know that the issue doesn't lie with the leads and the scope itself.

Now, with everything connected and prepared for action, check across the ground and the positive terminal. Watch closely; if you see a flat line appearing at 12V, it shows that your setup is solid, then you are ready to go.

Simply check the functionality of the oscilloscope and leads first by measuring the battery voltage.

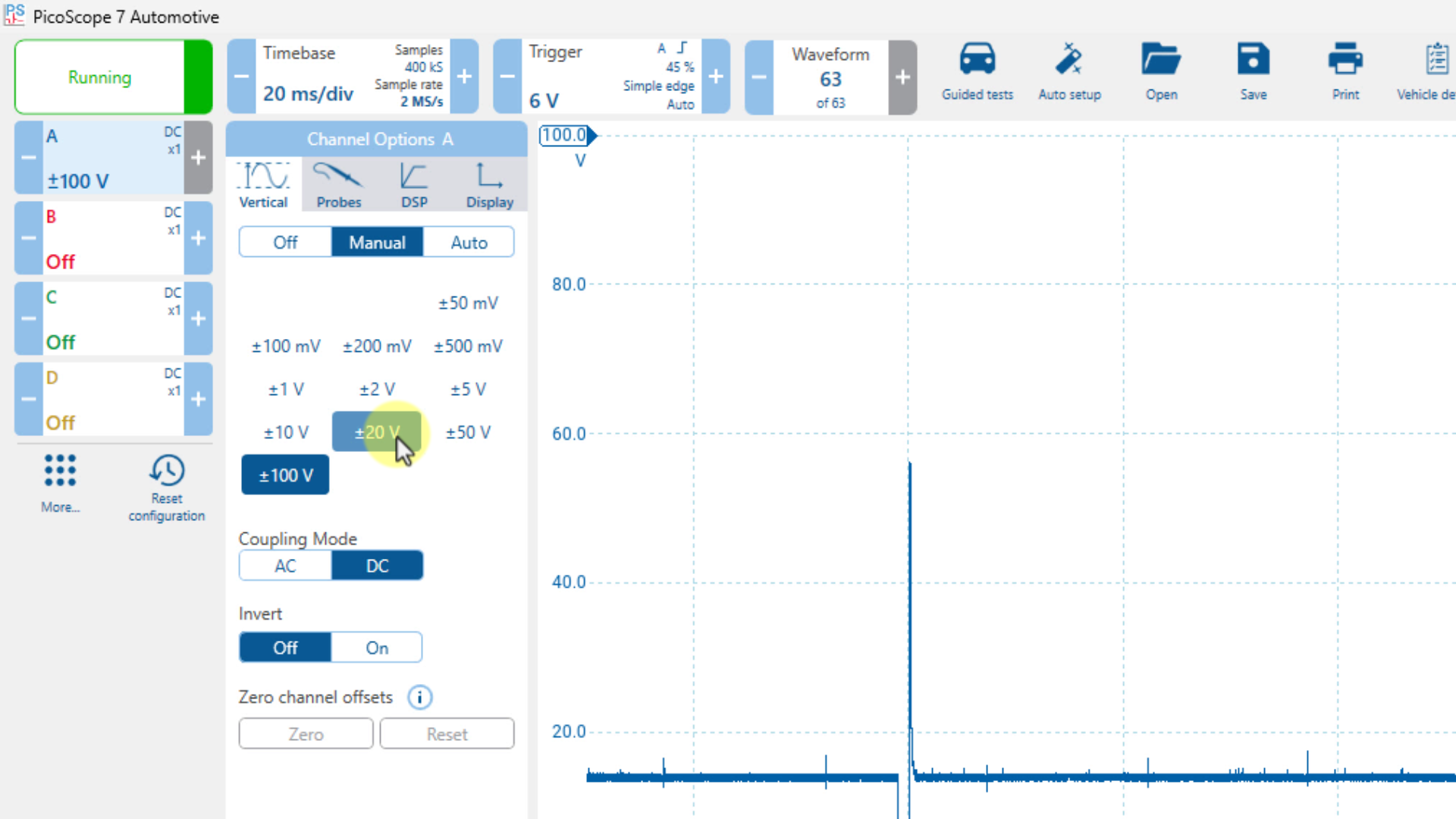

Tip 2: Set the Voltage Scale

Here's tip number two: make sure to set the voltage scale. Most oscilloscopes start up in ‘auto mode’ by default. That means that the oscilloscope decides which voltage is best based on what it can see on the leads, just like your voltmeter. But I sometimes find that the auto mode doesn't always quite work as it should. It can be overly sensitive depending on the time setting, and in cases where the waveform is on the edge of two ranges, it flicks between multiple ranges during the measurement; for example, 5 and 10V. It’s quite annoying!

To avoid this, know the voltage range you expect and manually set it before taking readings. So if you're measuring a sensor signal or CAN bus, it's likely to be around 5V. Battery voltage and pulse width modulated power supplies usually fall between 12 and 15V. And some injectors can reach up to 200V.

Something else to look out for; if you connect up to take a measurement and the trace is going off the top or off the bottom of the screen, it's likely that your voltage scale is set too low and needs increasing. I recommend making adjustments one incremental step at a time so you won’t go too far the other way and get confused.

Know the voltage range you expect and manually set it before taking any measurement.

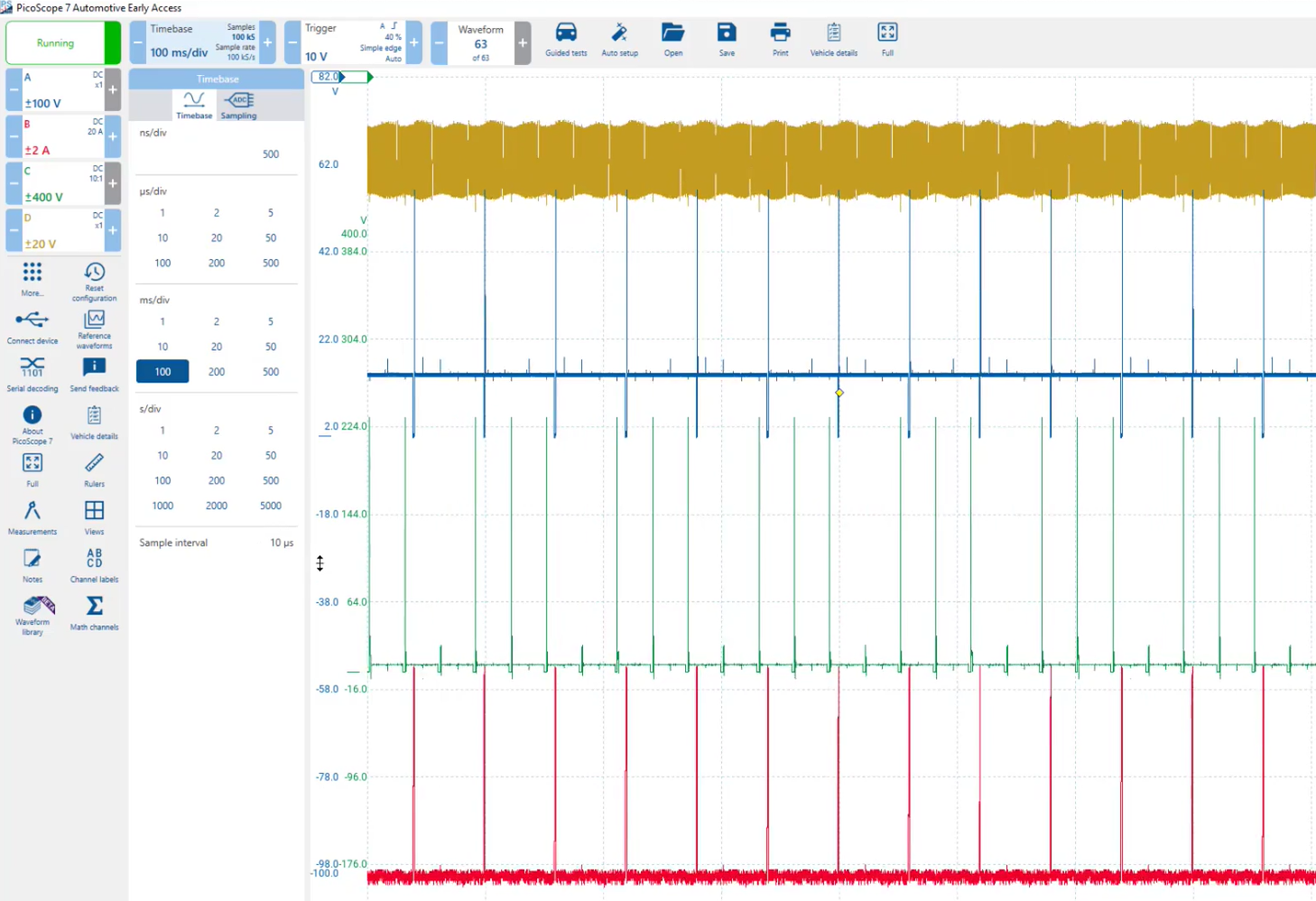

Tip 3: It’s All About Timing

Tip number three; configure the time setting. It can be difficult to remember which time setting you need for every single sensor or signal you measure on these vehicles. Is it milliseconds or microseconds? To simplify, I split signals into two categories; fast and slow.

Fast Signals

Generally, anything digital can be classed as a fast signal. This includes:

Camshaft sensors

PWM power supplies

CAN bus

LIN bus

Injector and ignition signals

For cam and crank sensors, injectors, and PWM, I suggest starting with 20 millisecond (ms) per division. For CAN bus, start around 50 microseconds (μs) per division, then adjust the time scale by one click at a time to get your desired waveform.

Slow Signals

A longer time scale is required to draw a picture over a period of time.

Analog pressure sensors

Potentiometers

Battery current draw

Start around 1 or 2 seconds per division. Most scopes have a feature where you can scroll back through the memory. It’s very useful in case you've got to leave the scope unattended while you go and rev the engine up or something like that. This feature ensures you won't miss any crucial data.

Our Oscilloscope Masters training package helps you better understand all the oscilloscope settings and apply them to automotive oscilloscope diagnostics!

We can split signals into two categories; fast and slow.

Tip 4: Hold it Right There!

Here comes tip number four; set your trigger. The trigger function is probably the oscilloscope’s best kept secret. Many times on training courses, I've watched over the shoulder of technicians who've tried to wait for the perfect opportunity to pause the scope, to get the exact waveform they wanted. For example, that injector pattern that keeps flashing on and off the screen.

The trigger function acts as a focal point for the oscilloscope, and holds the waveform in the same place on the screen. The trigger can perform various functions, but for most needs, the auto trigger is ideal.

How to Use the Trigger Function

Begin by navigating to the trigger settings on your oscilloscope.

Select the specific channel to which you want to apply the trigger.

Carefully adjust the trigger position by moving it above the zero volts line. This step is crucial for establishing a focus point on the waveform.

Notice that the pattern is now anchored to the trigger point, holding it in place on the screen.

You could then move the trigger to any desired position on the screen and to whichever voltage point of the waveform.

Keep in mind, the trigger should be set within the voltage range of the signal. If it's placed above or below the waveform, the trigger won't work. Also remember that you can set only one trigger at a time.

The Mechanic Mindset Oscilloscope Training package shows you different ways to use the oscilloscope trigger functions in different ways for different types of faults or testing.

The trigger function is probably the oscilloscope’s best kept secret.

Tip 5: Have Confidence!

So tip number five; have confidence! If you've followed all these steps and still not obtained a trace, you need to have confidence that there may actually be a fault on the line. Basic diagnostic procedures come into play. If all the other evidence suggests a fault, there probably is. Work your way back to identify circuit faults. If possible, double check against another known good signal. And make sure you have used the best method to test the circuit you are measuring. No matter how many scope settings you adjust, if there's no signal you're not going to get a trace!

Now, you don’t get the oscilloscope out every day. The Oscilloscope Masters training package is access for life so we’re always going to be there to help with your oscilloscope diagnostics.

Watch short, easy to understand videos to help you get the oscilloscope set up. Or ask for some support in our private community via the Mechanic Mindset mobile app!

Find out more and join our oscilloscope training here!

Confidence often stems from knowledge. If you possess more knowledge, you’ll exhibit greater confidence.